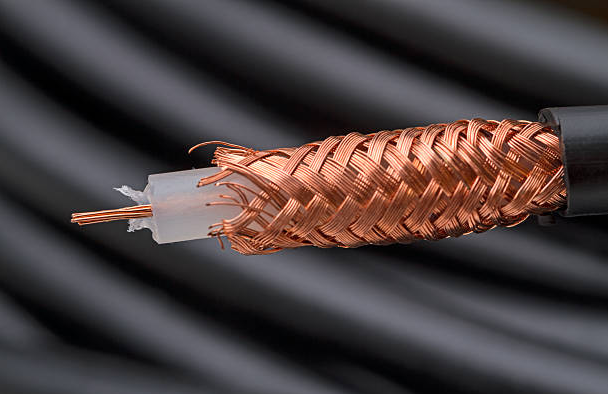

When it comes to electrical engineering and industrial applications, the choice of materials can make all the difference in performance, safety, and longevity. Among the many options available, Tin Coated Copper Wire stands out as a quintessential choice. It is often referred to as the “gold standard” in the industry, combining the superior conductivity of copper with the protective benefits of tin. But what makes it so special, and why is it indispensable for applications involving braided connectors and other critical components? Let’s explore.

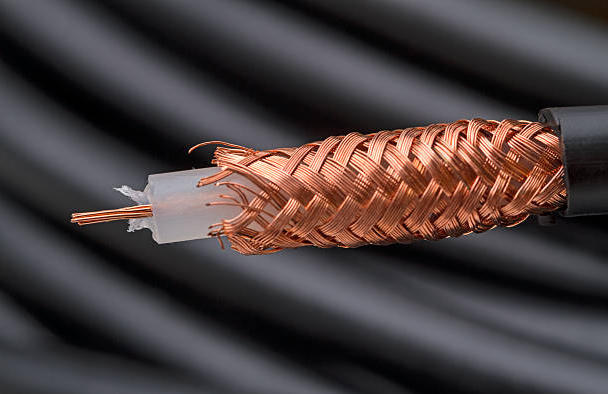

Unparalleled Corrosion Resistance

One of the primary advantages of tin coated copper wire is its remarkable resistance to corrosion. Copper, while an excellent conductor, is prone to oxidation when exposed to air and moisture. Over time, this oxidation can lead to a decline in electrical performance. The tin coating acts as a protective barrier, preventing oxidation and ensuring that the wire retains its efficiency even in harsh environments. This makes it particularly suitable for outdoor installations, marine applications, and industries where exposure to moisture or chemicals is a concern.

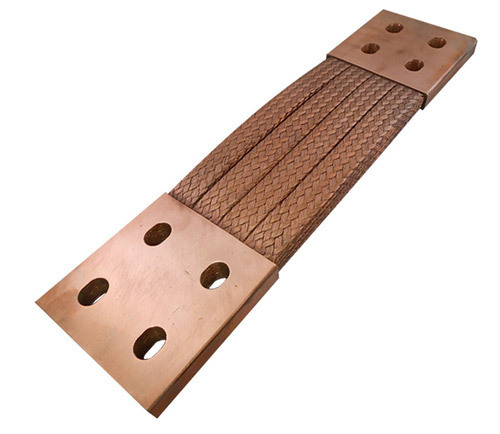

For braided connectors, which are often used in demanding conditions such as high-vibration environments or near corrosive substances, this added layer of protection ensures durability and reliability. Tin coated copper wires used in braided connectors provide consistent performance over time, reducing the need for frequent maintenance or replacement.

Enhanced Solderability

Tin coated copper wire is widely celebrated for its superior solderability. The tin coating facilitates the soldering process, ensuring strong and secure joints. This is especially critical in electrical applications where reliable connections are non-negotiable. Compared to bare copper wire, tin coated variants offer faster and cleaner soldering, minimizing the risk of cold joints or inconsistent connections.

In applications involving braided connectors, this feature becomes even more important. Braided connectors often require intricate assembly, and the ease of soldering tin coated copper wire simplifies the process while enhancing the overall quality of the connection.

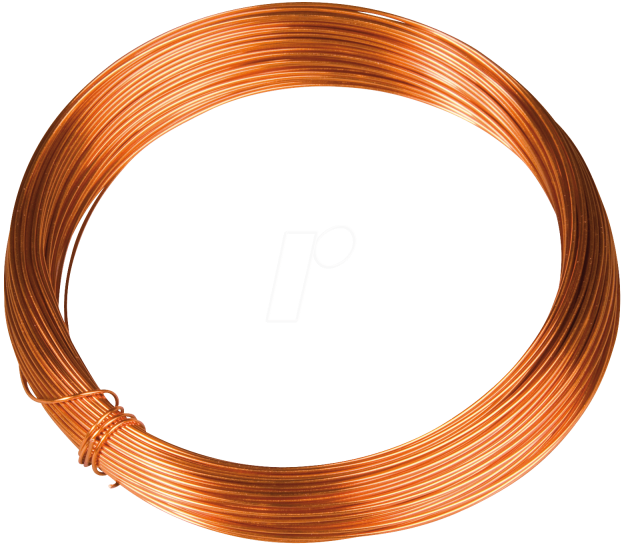

Improved Conductivity and Low Electrical Resistance

Copper is universally acknowledged for its excellent conductivity, and the addition of a tin coating does not compromise this property. Instead, it enhances the wire’s performance by maintaining low electrical resistance over prolonged periods. This is particularly advantageous in high-frequency applications where signal integrity is crucial.

For braided connectors, which serve as flexible electrical conduits or grounding systems, maintaining consistent conductivity is vital. Tin coated copper wires ensure that these connectors perform flawlessly, even in dynamic conditions.

Resistance to High Temperatures

In industrial settings, wires and connectors are often subjected to elevated temperatures. Tin coated copper wire exhibits excellent thermal stability, making it ideal for applications that require resistance to heat. The tin coating not only prevents oxidation at high temperatures but also maintains the mechanical and electrical integrity of the wire.

This property is particularly relevant for braided connectors used in the automotive, aerospace, and heavy machinery industries. These connectors frequently operate under extreme temperature fluctuations, and tin coated copper wires ensure consistent performance without degradation.

Flexibility and Durability

Another reason tin coated copper wire is considered the gold standard is its flexibility and durability. The tin coating provides an added layer of mechanical protection, reducing the risk of breakage or wear during installation and use. This flexibility is essential in applications involving braided connectors, which require wires to bend, twist, and conform to various shapes without compromising their structural integrity.

The combination of flexibility and strength makes tin coated copper wires an excellent choice for dynamic environments, such as robotic assemblies or movable electrical connections.

Cost-Effectiveness and Longevity

While the initial cost of tin coated copper wire may be higher than bare copper wire, its long-term benefits far outweigh the upfront expense. The enhanced durability, reduced maintenance needs, and prolonged lifespan make it a cost-effective solution for industrial and commercial applications.

For businesses relying on braided connectors in critical systems, investing in tin coated copper wires translates to fewer downtimes, lower replacement costs, and better overall performance. The longevity and reliability of these wires ensure a higher return on investment.

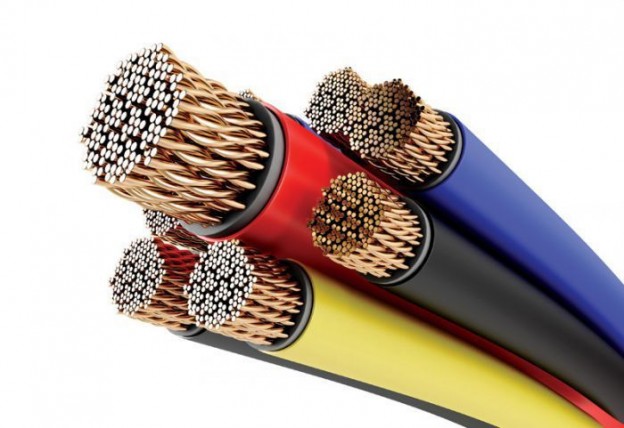

Wide Range of Applications

The versatility of tin coated copper wire is another factor that cements its reputation as the gold standard. It is used across various industries, including:

- Automotive: For wiring harnesses, grounding straps, and braided connectors.

- Aerospace: In systems that demand lightweight yet durable materials.

- Telecommunications: For signal transmission and grounding in high-frequency systems.

- Marine: For corrosion-resistant electrical systems in boats and offshore installations.

- Renewable Energy: In solar panels and wind turbines where durability is paramount.

In all these applications, braided connectors made with tin coated copper wires ensure optimal performance, reliability, and safety.

A Way Forward!

Tin coated copper wire’s unique combination of corrosion resistance, solderability, thermal stability, and electrical conductivity makes it an indispensable material for modern electrical applications. Its ability to perform consistently in harsh environments, coupled with its versatility, ensures that it remains a preferred choice for manufacturers and engineers alike.

For applications involving braided connectors, tin coated copper wire is not just a recommendation; it’s a necessity. Its superior properties guarantee reliability, longevity, and cost-efficiency, solidifying its position as the gold standard in electrical engineering. Whether you’re designing complex industrial systems or crafting intricate connectors, tin coated copper wire is the cornerstone of success.