The stranded wire is found to be far more flexible compared to the solid core wire that is of the same size. Moreover it is more useful in case you need a wire which has to be moved around often, for instance, like the wires in a robot arm. The solid wire, in comparison will be used where there is no demand for a lot of movement like the circuits on breadboard.

When you are choosing the type of wiring for any electrical project, you will have to look at many important factors. Depending on the kind of application you want and the amperage, you need to choose the right gauge and the kind of metal wire which will be best for the task. The wiring expert therefore tries to see the differences between the stranded wire and solid wire too when it comes to choosing the right wiring for the project.

Where will you use the stranded wire?

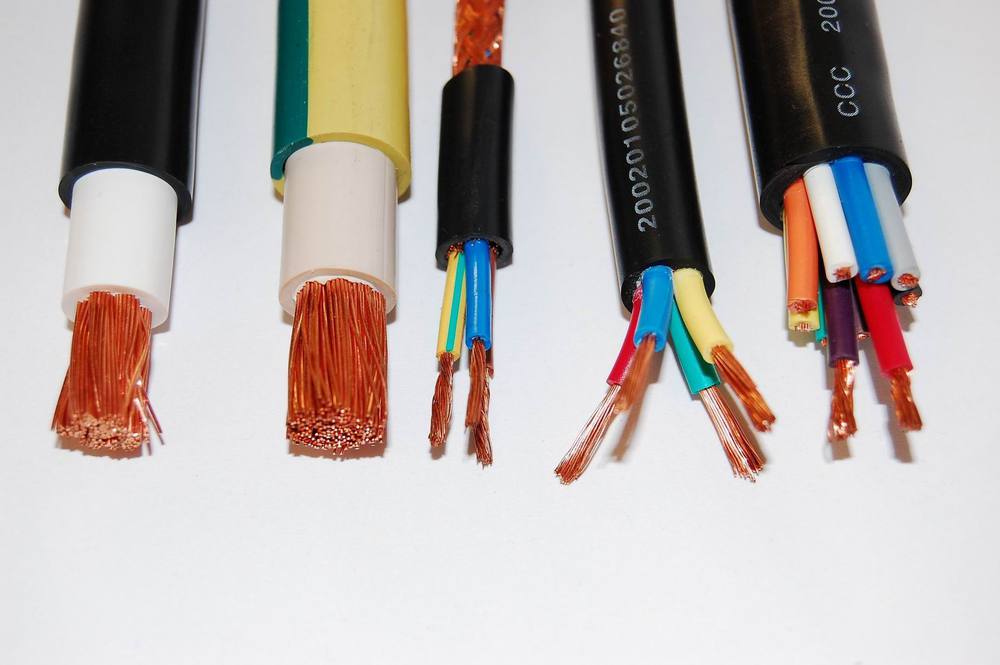

The solid wire is going to have one metal core while a stranded wire will be made up of many thin wires that are braided or twisted together to make one cohesive bunch of wires. Both these kinds of wires can be used for both domestic and commercial usage but each has its strength and weaknesses which help us decide on the right one for the application at hand. This is why the solid wire is typically used for all rugged-duty applications and outdoor uses where such wires are likely to be exposed to very adverse climatic conditions. The stranded wire, however, will be used more for intricate and sophisticated uses like in circuit boards and electronic devices. Here the wires are going to be well protected even though they may be twisted or bent while connecting them to electronic components.

There are many advantages of using the solid wire, the main ones being simplicity of use, durability and costs. Since the solid wire comprises of only one metal core, the chances of damage to it are less. But, when you must use these for bending and twisting like in the making of circuit boards the stranded wires are the best. They are most often used for vehicular applications and for robotics. Here, the solid wires are of no use because they do not have the malleability or strength to withstand such reshaping or frequent movements. The stranded wire is the best possible option for applications where a lot of lot of reshaping is needed. This wire is however not very good for preventing electronic interference since air channels in between these strands can increase skin effect which is triggered by the magnetic fields on wire surfaces.

Where costs are concerned, it is necessary to see the costs in the long term. The solid wire for instance will require less upfront investment as compared to the more expensive stranded wire. But the latter will last much longer in places where there is a lot of reshaping of wires and frequent alternations. The bare stranded copper wire gets made from electrolytic grade copper. It is therefore important to choose a manufacturer which complies with global quality standards when it comes to making products from such wires.

The submersible cable has been designed specially to work in marine environments. This is because this cable is known for providing electrical power even in wet conditions. The main reason why it has been able to do so is because of its rubber and plastic coating. This plastic coating allows the cables to withstand all liquid substances like oil, water or grease. The submersible cables have robust mechanical and electrical properties which can protect them from oil or water. Such cables can be found in single or multiple conductors. Their shapes or sizes will differ according to the applications for which they are used. They are mainly used for power conductors for pump motors. Besides, these cables can also be used for irrigation systems, underground mining, and drilling works. When identifying a manufacturer for buying these cables, it is important to check their credentials and reputation. You need a manufacturer which can offer you quality products at affordable rates and which have a buyer-friendly return and exchange policy.