In the world of electrical systems, choosing the right connectors is essential for ensuring reliability, safety, and performance. Among the many options available, braided flexible connectors stand out as a superior choice when compared to traditional electrical connectors. Their unique design and material properties offer a variety of advantages that make them ideal for many applications.

In this article, we’ll explore the reasons why braided flexible connectors are often the preferred choice over traditional connectors, especially in high-performance environments.

1. Enhanced Flexibility and Durability

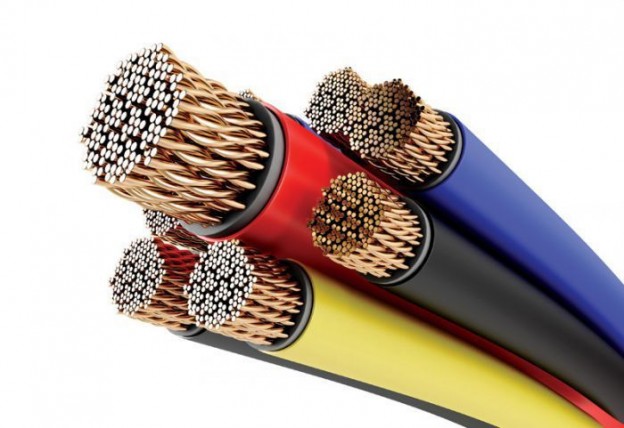

One of the most significant advantages of braided flexible connectors over traditional electrical connectors is their unparalleled flexibility. These connectors are designed to handle dynamic movements, vibrations, and flexing with ease. Traditional connectors, such as solid copper or crimped connectors, can be rigid and prone to damage from constant movement or expansion.

In contrast, braided flexible connectors, typically made of copper or other flexible materials, can withstand bending without compromising their structural integrity. This makes them perfect for applications in industries such as aerospace, automotive, and machinery, where movement and vibration are common.

Moreover, braided flexible connectors can easily adapt to changing positions and angles, providing a secure electrical connection without the risk of wire breakage or strain. Their flexibility extends their lifespan, especially in environments where flexibility and resilience are required, such as high-frequency systems or heavy-duty equipment.

2. Improved Electrical Conductivity

Braided flexible connectors, especially copper flexible connectors, offer excellent electrical conductivity. Copper is renowned for its superior ability to conduct electricity, and the braid design enhances this property by offering a greater surface area for the current to flow through. This makes braided flexible connectors ideal for high-power applications where efficient current flow is necessary to prevent overheating or loss of energy.

In traditional connectors, electrical conductivity may be limited by factors such as oxidation or material degradation over time. However, braided flexible connectors, particularly those made from high-quality copper wire, maintain excellent conductivity even in harsh conditions, which improves the overall performance and efficiency of the electrical system.

3. Resistance to Environmental Factors

Electrical systems often operate in challenging environments, where exposure to moisture, heat, chemicals, or dust can lead to the degradation of connectors. Braided flexible connectors offer superior resistance to environmental factors compared to traditional connectors.

The braided design, especially when paired with corrosion-resistant coatings or materials like copper, protects the conductor from external elements. This makes braided flexible connectors more reliable in outdoor, industrial, or marine environments, where harsh conditions are prevalent.

Furthermore, the robust construction of braided flexible connectors provides excellent resistance to temperature fluctuations, ensuring that they perform consistently across a wide range of operating temperatures. In applications where high temperatures are common, copper flexible connectors can effectively dissipate heat, preventing any potential damage to the electrical system.

4. Ease of Installation and Maintenance

Another reason to choose braided flexible connectors is the ease with which they can be installed and maintained. Traditional electrical connectors often require complex procedures or special tools for installation, which can slow down the process and increase the potential for errors. Braided flexible connectors, on the other hand, are easy to install due to their inherent flexibility. They can be bent or adjusted to fit into tight spaces, which is a significant advantage in systems with limited access or irregular configurations.

Additionally, braided flexible connectors require less maintenance over time. Their ability to maintain strong connections without the need for frequent re-tightening or inspection reduces downtime and ensures long-term reliability. Traditional connectors may require more frequent maintenance or tightening to ensure optimal performance but braided flexible connectors offer a “set it and forget it” solution for many applications.

5. Versatility Across Applications

Braided flexible connectors are incredibly versatile, offering compatibility with a wide range of electrical systems. Whether it’s for low-voltage or high-voltage applications, braided flexible connectors can accommodate various configurations and sizes to meet specific needs. This adaptability makes them suitable for industries ranging from telecommunications to power distribution. Copper flexible connectors are particularly useful in power transmission systems, where high current loads and consistent performance are essential.

In addition, these connectors are available in various designs, such as single-braid, multi-braid, and armored styles, allowing them to be customized based on the specific requirements of the application. This flexibility ensures that no matter the demands, there is a braided flexible connector that fits the bill.

6. Cost-Effectiveness in the Long Term

While the initial cost of braided flexible connectors may be higher than traditional connectors, they offer significant cost savings in the long run. Their durability, reliability, and resistance to environmental damage result in fewer replacements, less maintenance, and reduced downtime. This leads to lower operational costs and higher overall system efficiency. Furthermore, their improved electrical conductivity helps reduce energy losses, which can contribute to further cost savings in energy-intensive applications.

Key Takeaway!

Braided flexible connectors, particularly copper flexible connectors, offer distinct advantages over traditional electrical connectors, especially in applications that demand flexibility, durability, and high performance. With their superior flexibility, excellent electrical conductivity, resistance to environmental factors, ease of installation, and long-term cost-effectiveness, these connectors provide a reliable solution for various industries. When considering the optimal connector for your electrical system, the benefits of braided flexible connectors make them a clear choice for ensuring safety, efficiency, and longevity.