The growing global shift toward renewable energy technologies is driving a surge in the demand for materials that enable efficiency, longevity, and sustainability. One such material experiencing a sharp rise in demand is copper foil. Known for its excellent electrical conductivity, copper foil is integral to a wide range of renewable energy applications, particularly in solar power, wind energy, and energy storage systems. As renewable energy technologies advance, the need for copper foil becomes more pronounced, especially as industries continue to look for materials that are both reliable and environmentally friendly.

The Role of Copper Foil in Renewable Energy

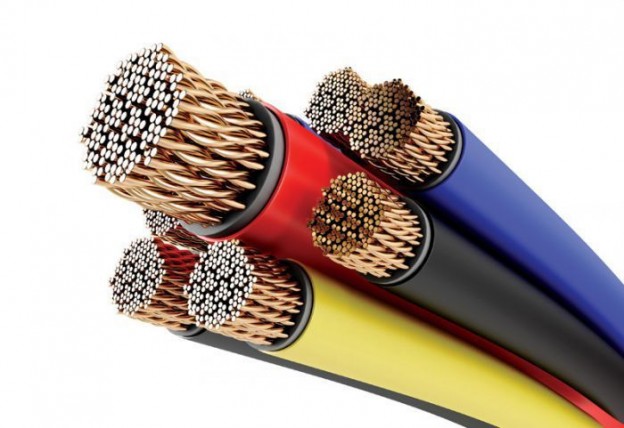

Copper foil, a thin sheet of copper, serves as a crucial component in many renewable energy devices, such as solar panels, energy storage batteries, and wind turbine control systems. Its versatility and conductive properties make it indispensable in energy-efficient systems, where performance and safety are paramount.

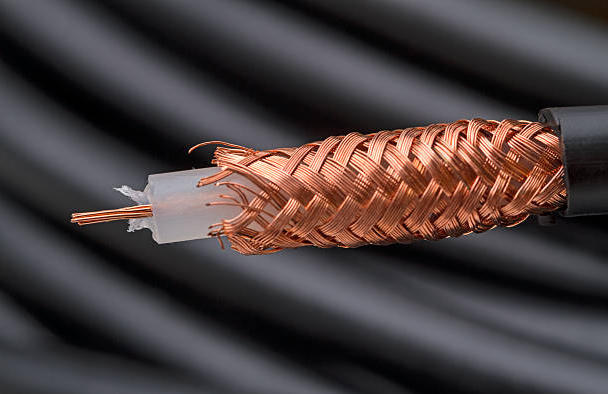

In solar energy systems, copper foil is commonly used in the manufacturing of photovoltaic (PV) cells. Solar panels harness sunlight to generate electricity, and copper foil is integral in connecting the layers of these cells, ensuring the smooth transfer of electrons. Copper’s superior conductivity allows solar panels to function efficiently, converting sunlight into usable electrical energy with minimal loss.

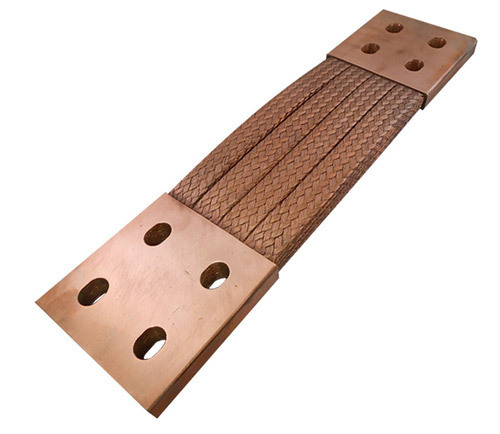

Likewise, copper foil plays a vital role in energy storage systems, such as batteries. With the rise of electric vehicles (EVs) and grid storage solutions, the demand for high-performance batteries has surged. Copper foil is used in the anodes of lithium-ion batteries, contributing to the overall stability and efficiency of these energy storage solutions. In these applications, copper foil enables better charge retention and faster charging speeds, which are crucial for the performance of EVs and the stability of renewable energy grids.

Additionally, wind turbines, which generate electricity through mechanical movement, require precise control systems to ensure safe and optimal performance. Copper foil is used in the control cables that connect the turbine’s sensors and motors, ensuring that energy is efficiently transmitted and that the system operates smoothly. As the wind energy sector continues to expand, the demand for copper foil in these control cables has become increasingly significant.

Why Copper Foil?

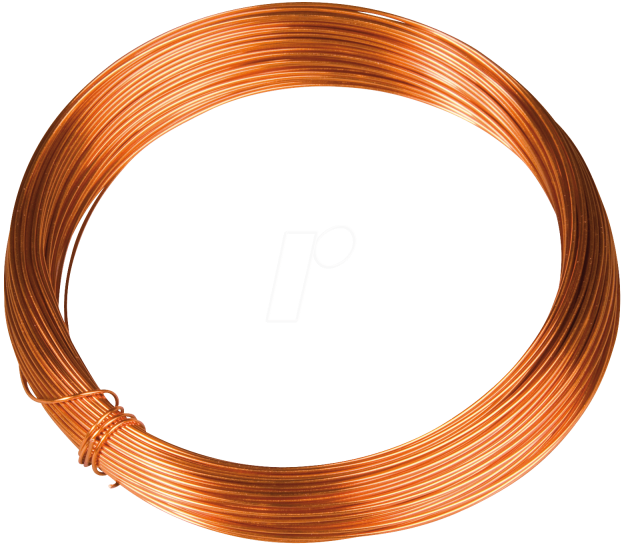

The preference for copper foil over other materials is driven by its exceptional electrical and thermal conductivity. In renewable energy applications, efficiency is critical, and copper provides a unique combination of low resistance, high durability, and reliable performance. These characteristics make it ideal for systems that rely on energy transfer and storage.

For example, in solar energy systems, copper foil ensures minimal loss during the energy conversion process. As electricity flows through solar cells, it encounters a small amount of resistance, but copper’s conductivity ensures that the energy loss is kept to an absolute minimum. This leads to better overall performance and greater energy yield from solar panels.

In energy storage systems, copper foil contributes to faster and more efficient charging and discharging processes. The use of copper in lithium-ion batteries enhances their ability to store and release energy quickly, making them a preferred choice for both consumer electronics and large-scale energy storage.

Moreover, copper is a recyclable material, making it an eco-friendly choice for industries striving to reduce their carbon footprint. This sustainability aspect is increasingly important in the renewable energy sector, where minimizing environmental impact is a priority. Copper’s ability to be recycled without losing its integrity adds to its appeal, aligning with the green credentials of renewable energy technologies.

The Role of Copper Wire Manufacturers in Meeting the Demand

The growing demand for copper foil is not just driven by the renewable energy sector but is also supported by copper wire manufacturers who are scaling up production to meet the needs of these emerging technologies. Copper wire manufacturers are playing a crucial role in ensuring that there is a steady supply of high-quality copper foil for use in solar panels, batteries, wind turbines, and more.

As industries across the globe strive to transition to greener energy solutions, copper wire manufacturers are tasked with producing copper foil that meets the specific requirements of renewable energy technologies. This includes ensuring that the copper foil is thin, flexible, and durable enough to withstand the rigors of high-performance energy systems.

In particular, the demand for control cables in wind turbines and other renewable energy technologies is increasing. Copper foil is integral to these cables, providing the necessary electrical conductivity to ensure that control systems operate smoothly. Copper wire manufacturers are now focused on producing copper foil that is not only cost-effective but also capable of meeting the precise technical demands of the renewable energy sector.

Conclusion:

The surge in demand for copper foil can be attributed to its essential role in the ongoing transformation of the global energy landscape. As the world increasingly relies on renewable energy sources, copper foil becomes an indispensable component of solar, wind, and energy storage systems. The superior conductivity, efficiency, and recyclability of copper make it the material of choice for these technologies.

With renewable energy technologies continuing to advance, the need for copper foil will only grow. Copper wire manufacturers and suppliers are critical in meeting this demand, ensuring that industries have access to the high-quality materials they need to support sustainable energy solutions. As we continue to push toward a cleaner, greener future, copper foil will undoubtedly remain at the forefront of renewable energy innovation.