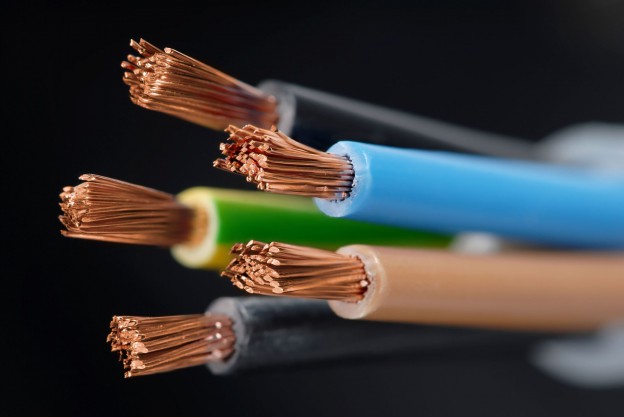

Copper wires are like the quiet heroes of our electrical world. Think of copper as the ultimate team player among metals when it comes to carrying electricity. Its atoms are just the right size and structure, allowing electricity to flow through them smoothly and efficiently. This makes copper a top choice for making wires that power up our homes, gadgets, and industries.

Picture your phone charger or the cables in your walls – chances are they’re made of copper. Its ability to handle high electrical currents without overheating or losing too much energy makes it indispensable in electrical applications. Plus, it’s pretty durable, so those wires tend to last a long time without wearing out.

Without copper wires, our modern world would be a tangle of problems. We wouldn’t have reliable electricity for lighting, heating, or running appliances. Industries rely on copper wires for everything from telecommunications to transportation systems. Even renewable energy sources like solar panels and wind turbines depend on copper to carry the power they generate.

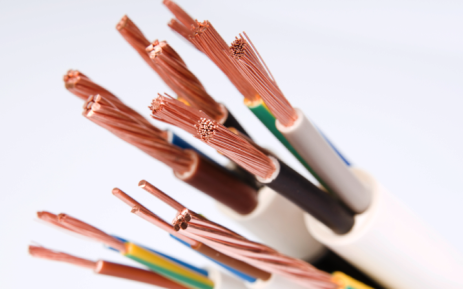

Bare Copper Wires: Characteristics and Uses

Bare copper wires are simply copper wires without any additional coatings or coverings. They retain all the natural properties of copper, which is excellent for conducting electricity. One of copper’s standout features is its high electrical conductivity, meaning it allows electricity to flow through it with minimal resistance. This makes bare copper wires ideal for situations where efficient transmission of electrical signals or power is crucial.

You’ll often find bare copper wires in electrical systems, such as in homes for wiring circuits or in power distribution networks. They’re also used extensively in electronic devices like computers, televisions, and mobile phones, forming intricate pathways that carry signals and power throughout these gadgets.

Because of copper’s ability to handle high current loads without overheating, bare copper wires are preferred in applications where durability and reliability are paramount. They’re also resistant to corrosion, which adds to their longevity and suitability for outdoor or harsh environments.

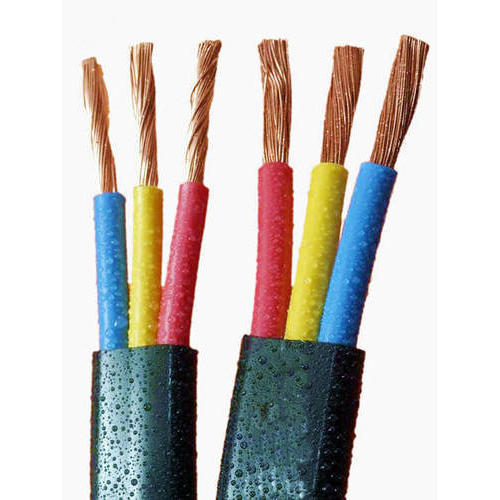

Bunched Copper Wires: Advantages and Applications

Bunched copper wires are essentially multiple thin copper strands twisted or grouped. This design increases their flexibility while retaining the excellent electrical conductivity of copper. Their composition allows them to bend and move more easily compared to solid copper wires, making them perfect for applications that require flexibility without compromising on performance.

One major advantage of bunched copper wires is their ability to withstand repeated bending and stretching without breaking, making them highly durable. Their flexibility also makes them easier to install in tight spaces or complex configurations, reducing installation time and costs.

Because of their excellent conductivity, bunched copper wires are commonly used in electrical connections that require reliable transmission of signals or power. They’re found in various applications such as automotive wiring harnesses, where flexibility is crucial due to constant movement and vibrations. In electronics, they’re used in cables for audio/video equipment, computers, and telecommunications, ensuring smooth and uninterrupted signal transmission.

Their durability and flexibility also make them ideal for industrial applications, like machinery and equipment wiring, where they can handle the rigours of heavy usage and harsh environments. Overall, bunched copper wire offer a winning combination of flexibility, durability, and conductivity, making them a go-to choice for a wide range of electrical and electronic applications.

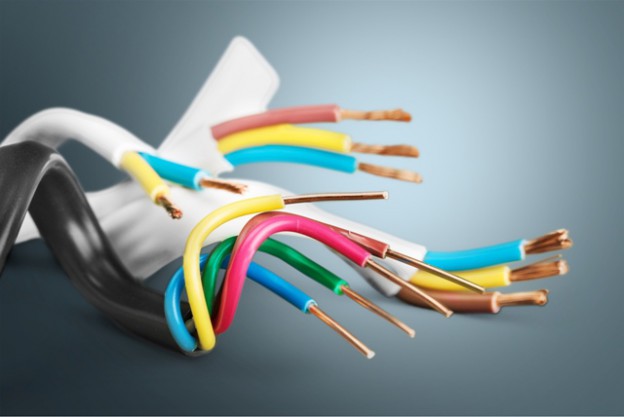

Comparison: Bunched vs. Bare Copper Wires

Bunched and bare copper wires have distinct characteristics that make them suitable for different applications. In terms of conductivity, both types excel due to copper’s natural ability to conduct electricity efficiently. However, bunched copper wires, with their multiple strands, offer slightly higher conductivity than bare copper wires. This makes them preferable for applications where maximizing electrical efficiency is critical, such as in high-performance electronics or power transmission systems.

When it comes to flexibility and ease of installation, bunched copper wires take the lead. Their multiple strands allow for greater flexibility, making them easier to bend and maneuver around tight spaces or complex configurations. This flexibility reduces the chances of damage during installation and enables smoother routing, especially in applications where constant movement or vibrations are common, like in automotive wiring or machinery.

Cost considerations often favour bare copper wires, as they are simpler in construction and typically more cost-effective to produce. However, bunched copper wires offer superior performance in terms of conductivity and flexibility, which can offset their initial higher cost in applications where these factors are crucial. Overall, the choice between bunched and bare copper wires depends on specific requirements such as conductivity needs, flexibility, installation ease, and budget constraints, with each type offering unique advantages for different scenarios.

Final Thoughts

Considering the characteristics and applications of bunched and bare copper wires, it’s clear that both play important roles in various electrical and electronic systems. Bare copper wires, with their simplicity and cost-effectiveness, are suitable for standard electrical wiring where conductivity and flexibility are not primary concerns. On the other hand, bunched copper wires shine in applications requiring enhanced conductivity, flexibility, and durability, such as in high-performance electronics, automotive wiring, and industrial machinery.

The choice between bunched and bare copper wires ultimately boils down to specific project requirements. If you need maximum electrical efficiency, flexibility, and resilience to bending, bunched copper wires are the way to go. However, for simpler installations where cost is a significant factor and extreme flexibility isn’t necessary, bare copper wires provide a reliable and economical option.

Understanding the strengths and weaknesses of each type allows for informed decision-making when selecting the appropriate wiring solution for a particular application. Whether it’s optimizing conductivity, ensuring flexibility, or staying within budget constraints, both bunched and bare copper wires offer valuable options for meeting diverse electrical and electronic needs.