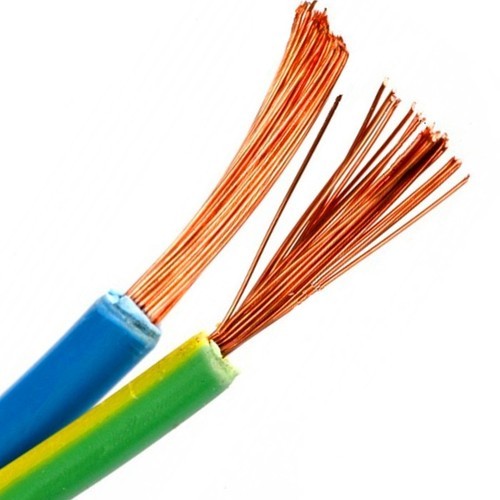

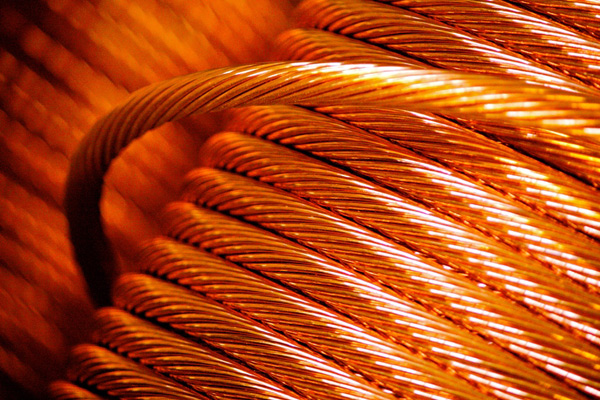

Copper is a highly efficient conductor of electricity, meaning that it can transmit electrical current with minimal resistance. This makes it an ideal material for use in electrical wiring, as it can help to ensure that electricity flows smoothly and efficiently throughout the system.

Copper wire is also highly resistant to corrosion, making it a durable and long-lasting choice for use in electrical systems. It is also easy to work with, as it can be easily bent, twisted, and shaped to fit a variety of applications.

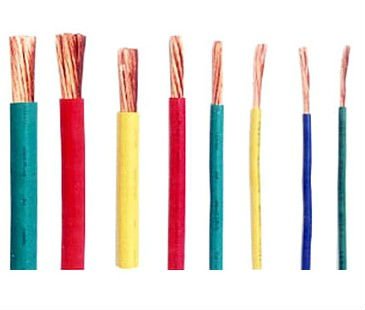

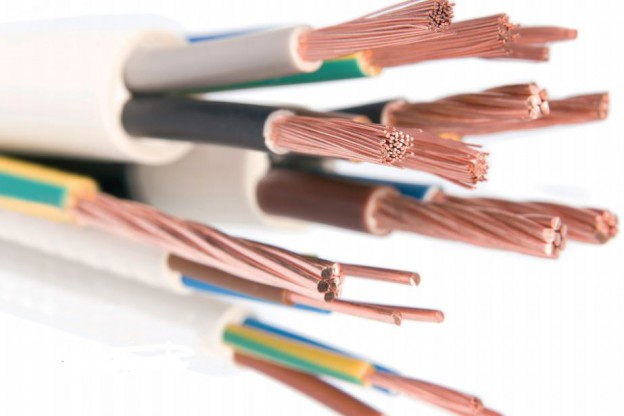

There are a few different types of copper wire that are commonly used in electrical systems, including solid copper wire and stranded copper wire. Solid copper wire is made up of a single, solid strand of copper and is typically used in applications where high levels of conductivity are required. Stranded copper wire, on the other hand, is made up of a bundle of smaller copper strands that are twisted together to form a larger wire. Stranded copper wire is more flexible than solid copper wire and is often used in applications where the wire needs to be bent or shaped.

Overall, copper wire is a reliable and efficient choice for use in electrical systems, and it is widely used in a variety of applications, from residential wiring to automotive wiring and beyond.

Common Issues with Electrical Copper Wire

Copper wire is a popular choice for use in electrical systems due to its high conductivity and durability. However, like any electrical component, electrical copper wire can sometimes experience issues that can disrupt the functioning of an electrical system. Here are five common issues that can arise with electrical copper wire, along with some tips for troubleshooting and resolving these problems:

- Corrosion: Electrical copper wire can corrode over time due to exposure to moisture, acid, or other corrosive substances. If you notice that your electrical copper wire is showing signs of corrosion, such as green or blue discoloration, you should replace it as soon as possible to prevent electrical problems.

- Loose connections: Electrical copper wire connections can become loose over time, leading to intermittent electrical issues or even a complete failure of the system. To troubleshoot loose connections, you can try tightening the connections or rewiring the system if necessary.

- Wire damage: Electrical copper wire can be damaged by physical stress, such as bending or crushing, or by exposure to heat or flame. If you notice that your electrical copper wire is damaged, you should replace it to prevent electrical problems.

- Overloading: Electrical copper wire has a specific current-carrying capacity, and if it is overloaded, it can cause electrical issues or even a fire. To prevent overloading, make sure that you are using the appropriate size of electrical copper wire for your electrical system and that you are not exceeding the recommended load for the wire.

- Poor installation: Electrical copper wire that is not installed correctly can lead to a variety of electrical issues. To troubleshoot problems caused by poor installation, you may need to re-install the Electrical copper wire or hire a professional electrician to fix the issue.

How to Troubleshoot Common Electrical Copper Wire Issues?

If you are dealing with corrosion, it is important to identify the cause of the corrosion and take steps to prevent it from occurring again in the future. For example, if the corrosion is caused by exposure to moisture, you may need to improve the ventilation or waterproofing in your electrical system. If you are having issues with loose connections, it is important to make sure that the connections are tightened securely and that the wire is not damaged. You may also need to ensure that the wire is clamped or secured properly to prevent it from moving or vibrating.

If you are dealing with damaged wire, it is important to replace it as soon as possible to prevent electrical problems. Make sure to use the appropriate size and type of wire for your electrical system, and follow all safety precautions when working with electrical components.

To prevent overloading, it is important to pay attention to the current-carrying capacity of your copper wire and make sure that you are not exceeding its recommended load. You should also be mindful of the overall load on your electrical system and make sure that it is not overloaded. If you are experiencing issues with poor installation, you may need to reinstall the copper wire or hire a professional electrician to fix the problem. Make sure to follow all relevant electrical codes and guidelines, and use the appropriate tools and techniques when installing electrical components.

Conclusion

In conclusion, copper wire is a reliable choice for use in electrical systems, however, like any electrical component, electrical copper wire can sometimes experience issues that can disrupt the functioning of an electrical system. Some common issues that can arise with copper wire include corrosion, loose connections, wire damage, overloading, and poor installation.

To troubleshoot these issues, it is important to identify the root cause of the problem and take the appropriate steps to fix it. This may involve replacing the damaged wire, tightening loose connections, improving ventilation or waterproofing to prevent corrosion, or re-installing wire that has been poorly installed.

Thus, it is important to be vigilant in maintaining your electrical system and paying attention to any issues that may arise with your copper wire. By taking prompt action to address these issues, you can help to ensure the safety and reliability of your electrical system.

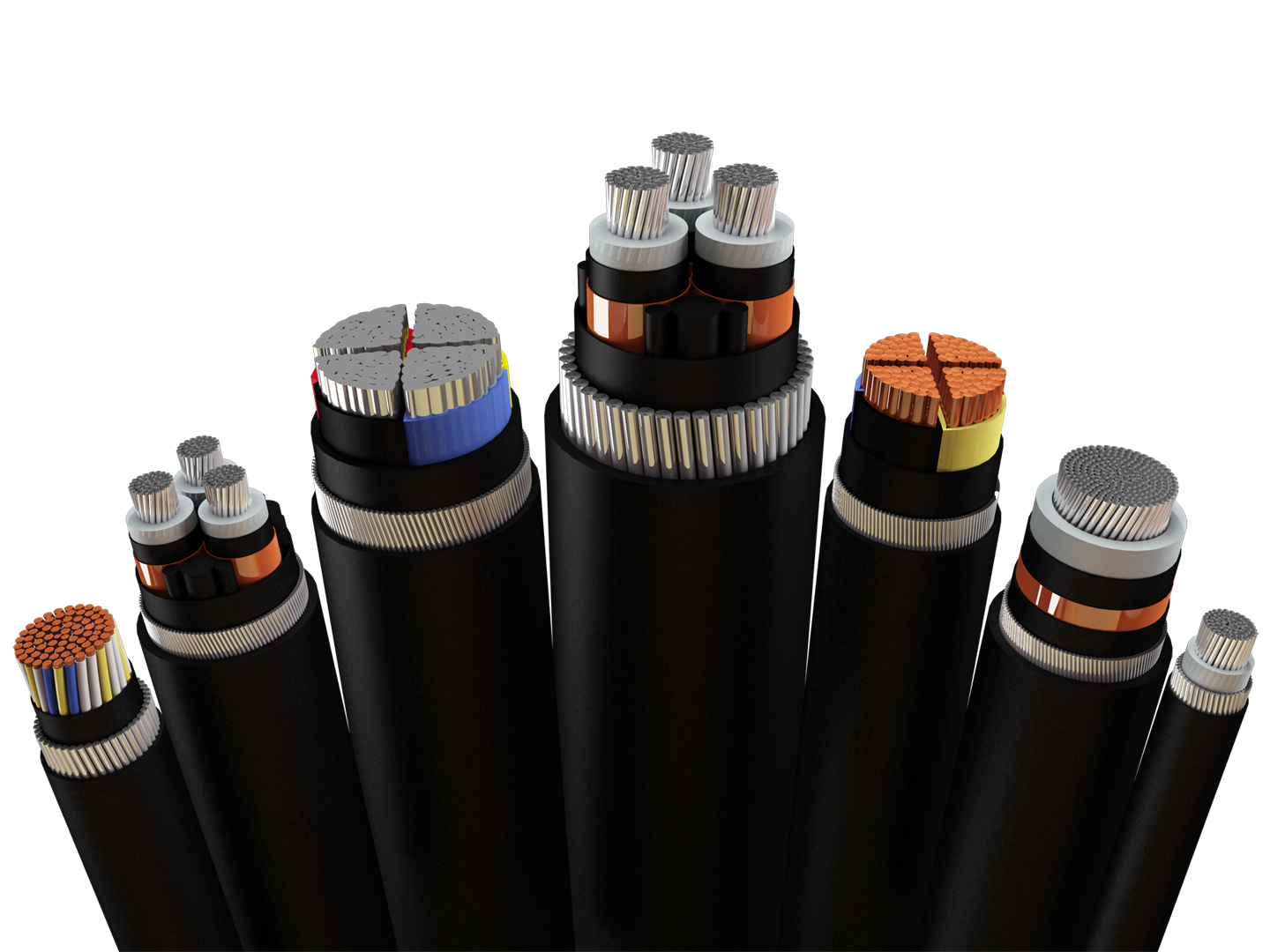

Major types of electrical cables

Major types of electrical cables