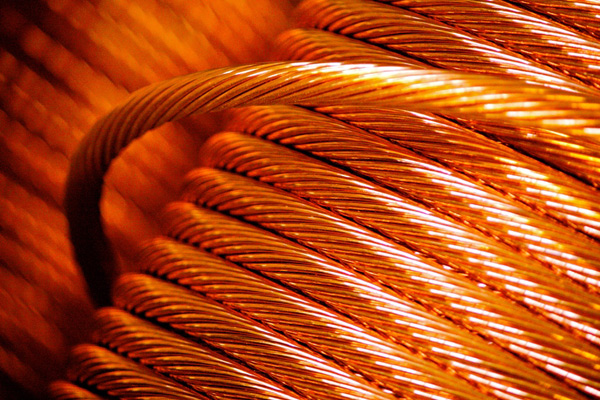

Since copper wire cables have a high electrical conductivity, they are the most popular choice for electrical wiring. Despite copper’s high conductivity, it is not needed to heat it up too much to transfer electricity through it. Wires of this type are used as the primary component by the cable industry to create several different types of wires. To name a few, copper is used to manufacture tinsel wire, underwater winding wire, copper strip, special cable, and control cable. A number of other equipment and instruments are also produced using copper.

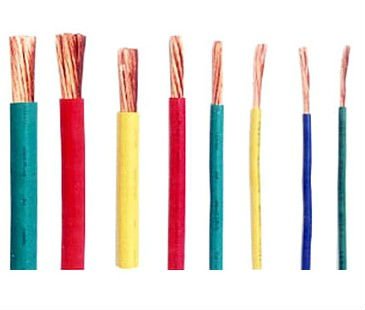

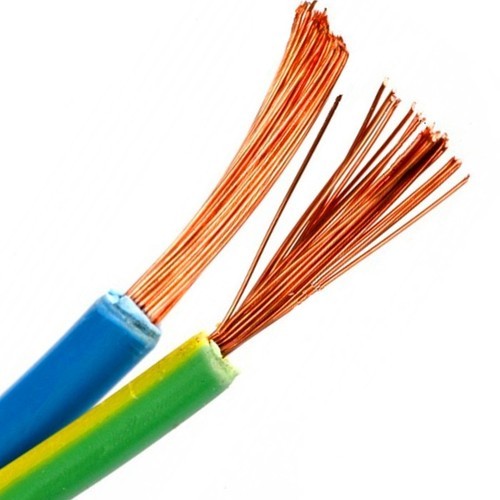

The additional metal needed to produce a power cord is iron. PVC, which is utilized in both coated and insulated PVC wire formed from this metal, is the most common plastic used to coat electrical wires. In addition to being significantly more fire resistant, less durable, and more inexpensive, it offers good insulating properties.

Today, wires made from these metals are the most preferred metals for residential and commercial wiring. Copper has a number of features that make it stand out from other metals, including its flexibility and resistance to metal depletion. A very practical way to shape and size them is through drawing, thanks to the metal’s malleability and durability. Additionally, copper wire cables are able to withstand any climatic condition, from extreme cold to intense heat.

Braided wire is commonly used as a flexible link in electric appliances, storage batteries, and electric stoves. They are made from multiple-threaded circular copper wire that is tinned for flexibility and is of the highest quality. An electrical resistance of relatively low DC is provided by copper wire braided with a DC electrical resistance of copper. Apart from being corrosion-resistant, copper strips are also used in automatic machines to maximize production and minimize electricity consumption. Manufacturers of copper strips provide customized strips based on customer requirements. Bare copper strip serves as a valuable raw material for numerous industries and is most suitable for areas with highly salinized soil.

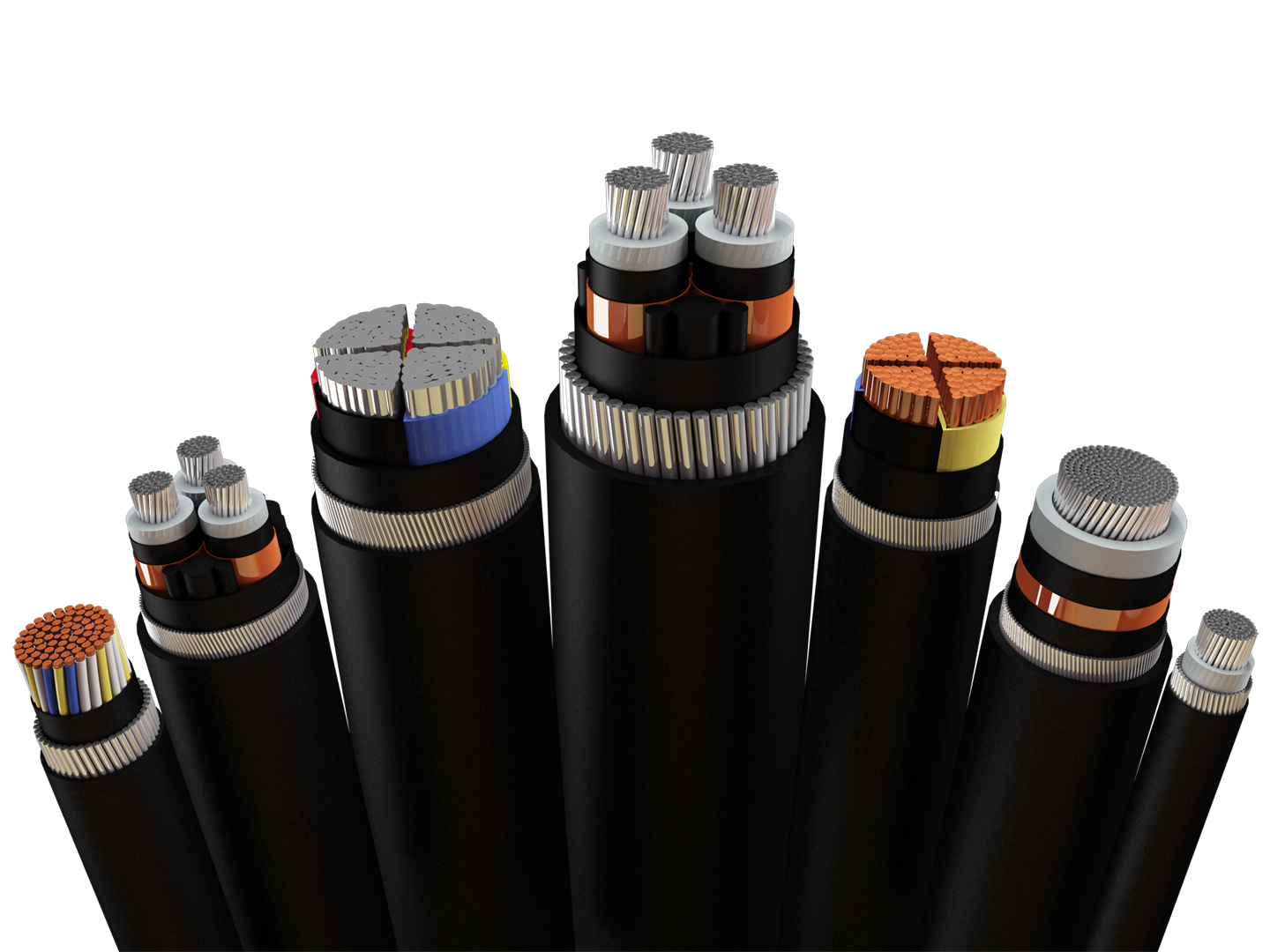

Copper and iron-based electric power cables are widely used for electricity delivery. Low voltage electrical cables called copper braided wires are created by wrapping copper foil strands around textile cores or by covering them in PVC. Copper wire is offered in a variety of shapes and sizes due to the country’s growing need for it. Copper wires are frequently utilized for both home and business electrical products, demonstrating their importance all over the world. Due to the rise in demand for copper wires, there have been notable rises in the number of copper wire suppliers globally.

Major types of electrical cables

Major types of electrical cables