Choosing the correct type of copper wire ensures performance and safety in electrical wiring. Two stand out among the various options: braided copper wire and solid copper wire.

Each type offers unique characteristics and benefits tailored to different applications and scenarios.

In this blog, we’ll explore the distinctive features of braided and solid copper wire, shedding light on their advantages and best-use cases. Let’s dive in and discover which type of copper wire is the ideal match for your next project.

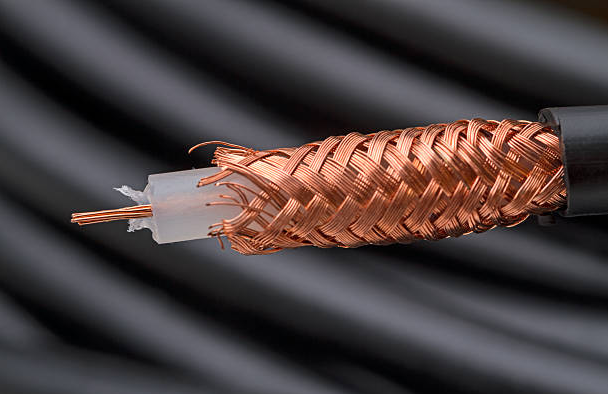

Understanding Braided Copper Wire

The braided copper wire consists of multiple thin strands of copper twisted together. This construction makes the wire more flexible and durable. It is often used when the wire needs to move frequently or be bent into various shapes.

Braided copper wire is known for its excellent conductivity and flexibility, making it ideal for a range of applications, including:

- Braided Copper Strip: Used in high-flexibility connections and grounding applications.

- Braided Copper Rope: Employed in heavy-duty electrical connections and grounding where flexibility is essential.

- Braided Connectors: These are common in the automotive and aerospace industries for connecting different circuit parts.

Understanding Solid Copper Wire

On the other hand, solid copper wire consists of a single, solid strand of copper. It is sturdy and less flexible compared to braided copper wire. This type of wire is typically used in applications where the wire does not need to move and where durability and strength are paramount. Solid copper wire is often used in:

- Bare Copper Strip: Utilized in grounding and bonding applications.

- Permanent installations within buildings and infrastructure.

- Applications requiring minimal interference and maximum conductivity.

Key Differences Between Braided and Solid Copper Wire

1. Flexibility and Durability:

- Braided Copper Wire: The multiple strands in braided copper wire provide superior flexibility. This flexibility is essential in applications where the wire will be moved or bent regularly, such as robotics, machinery, and automotive applications.

- Solid Copper Wire: Solid copper wire is more rigid but offers greater durability under physical stress. It is less prone to breaking when subjected to high tension or compression forces, making it suitable for fixed installations.

2. Conductivity:

- Braided Copper Wire: Offers excellent conductivity due to the high surface area of the multiple strands. This makes it efficient in applications requiring high current flow and minimal resistance.

- Solid Copper Wire Also provides excellent conductivity but may have a slightly lower surface area than braided copper wire. However, solid copper wire is highly effective for applications requiring straightforward, uninterrupted current flow.

3. Applications:

- Braided Copper Wire is ideal for dynamic environments where the wire must bend and move. Examples include audio and video equipment, machinery, and vehicles.

- Solid Copper Wire: Best suited for static applications like residential wiring, electrical panels, and grounding systems.

4. Installation:

- Braided Copper Wire: Its flexibility makes installing in tight or complex spaces easier. It can be maneuvered around obstacles and into intricate pathways without kinking or breaking.

- Solid Copper Wire: More challenging to install in tight spaces because of its rigidity. However, its straightforward structure makes it easier to connect to terminals and connectors.

5. Cost:

- Braided Copper Wire: Typically more expensive than solid copper wire because of the intricate manufacturing process and the added benefits of flexibility and durability.

- Solid Copper Wire: Generally more cost-effective, making it a popular choice for large-scale installations where cost is critical.

Advantages of Braided Copper Wire

- Flexibility: Essential for applications requiring frequent movement or bending.

- Durability: Resistant to vibration and mechanical stress, reducing the risk of breakage.

- Enhanced Conductivity: The high surface area of the strands allows for efficient electrical flow.

- Versatility: Suitable for various applications, from household electronics to industrial machinery.

Advantages of Solid Copper Wire

- Strength: Provides robust performance in static installations.

- Ease of Connection: Simple to connect to terminals, reducing installation time.

- Cost-Effective: More affordable for large-scale installations and straightforward applications.

- Reliability: Offers consistent performance with minimal maintenance.

Choosing the Right Type for Your Needs

When deciding between braided copper wire and solid copper wire, consider your project’s specific requirements. If your application involves movement, vibration, or complex routing, braided copper wire is likely the better choice. Its flexibility and durability in dynamic environments make it indispensable in such scenarios.

Solid copper wire is the preferred option for fixed installations where cost efficiency and straightforward connectivity are paramount. Its strength and reliability ensure long-term performance in stable environments.

Final Words

Both braided copper wire and solid copper wire have their unique advantages and are suited to different applications. Understanding their key differences and strengths will help you make an informed decision based on your needs.

If you are looking for high-quality braided copper wire, strip, rope, bare copper strip, or braided connectors, consider Rajsthanelectrics. They offer a wide range of products designed to meet the highest standards of quality and performance. Whether your project requires the flexibility of braided copper wire or the robustness of solid copper wire, Rajsthanelectrics has the right solution for you. Visit Rajsthanelectrics to explore their offerings and find the perfect copper wire for your needs.