An Armoured Cable is a type of cable covered in a metal sheath. It is used to conduct power. Mostly, it is a bundle of wires that are encased in a metal covering or tube which may be further covered in a plastic insulation layer.

How this goes is that at the core of the cable is a wire bundle of copper wires that are covered in plastic insulation to separate them from each other and the metal covering. The metal covering saves these wires from wear and tear and physical impact. It is generally a long metal strip that is wound around the bundle, giving it an almost spring like appearance. These cables are heavy and extremely difficult to bend.

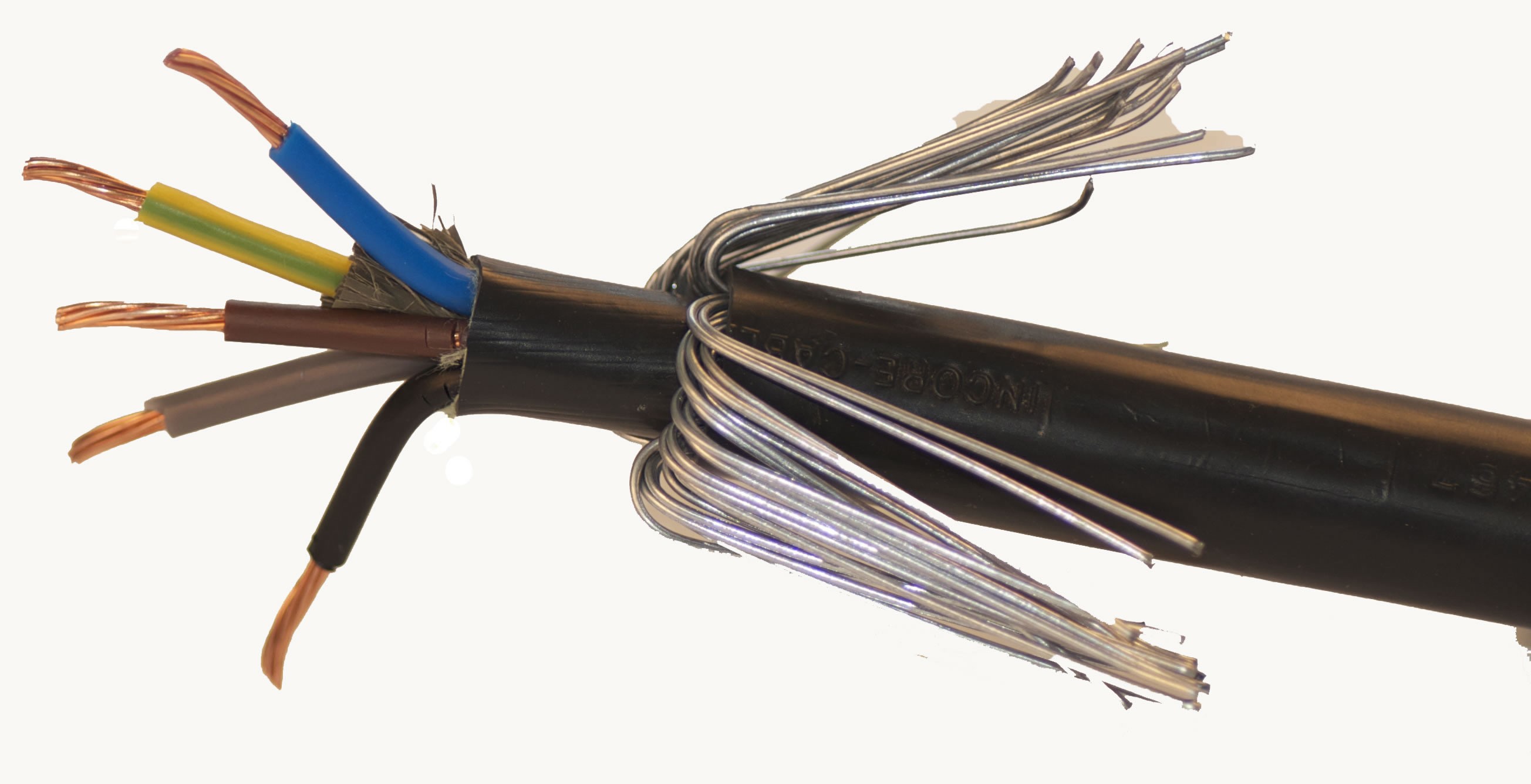

Composition of an armoured cable

- First is the conductor, which is usually just plain stranded copper.

- To protect the conductor from water damage, insulation is used. This also protects the conductor from the metal component – the armour.

- Now comes the bedding, which is PVC. This works like a barrier between the inner components of the conductor and the outer parts.

- The armour is placed over the bedding. It provides protection to the cable from any kind of stress. It is also used sometimes as the ‘earth’ cable.

- The last part is cable sheathing which is used to protect the inner cable components. It also works to safeguard against any mechanical damage.

While it is true that only one particular type of cable is called an Armoured Cable, it is used as a generic term for all power cables that are encased in metal. There are three basic types of metal covered cables and each of these has its specific features.

BX is the oldest form of Armoured Cable. It was made during the Second World War and used for decades post that. However, its grounding system was poor and it also had a tendency to leak. With time came modifications. True Armoured Cable came around. It is a heavier alternative to BX, featuring a better grounding system and waterprooofing, heavier internal insulation, and tougher design.

BX is the oldest form of Armoured Cable. It was made during the Second World War and used for decades post that. However, its grounding system was poor and it also had a tendency to leak. With time came modifications. True Armoured Cable came around. It is a heavier alternative to BX, featuring a better grounding system and waterprooofing, heavier internal insulation, and tougher design.

Uses of these cables

Armoured Cables are primarily used in industrial applications, like in cable trays and raceways. Many cities and municipalities allow the use of these cables in residential and commercial applications. They are most suitable for underground cabling, such as in sewers or underground transport networks, or outdoor walls via cable cleats.

When these cables are used in public places, it should feature a special sheath which is called LSLH (Low Smoke, Low Halogen). In case of a fire, this sheath produces less smoke and halogen, thus making it a safer alternative to standard cables.

Steel wiring is used only in multicore cables. This is to prevent the cable from overheating, thus leading to the possibility of fire. In case of single core, aluminium is generally preferred.