There are two ways to transport electricity: underground cable and overhead cable. Design of power cables various accordingly. Their chief purpose is to transmit and distribute power. Electric power cable is an assortment of one or multiple individually-insulated conductors held together through a sheath. You can install them within buildings as permanent wiring or bury them in ground or install them overhead. You need not always encompass them in a structure. You can run them exposed too. Flexible cables are great for mobile machinery, tools, and portable equipment.

Electric power cable is an assortment of one or multiple individually-insulated conductors held together through a sheath. You can install them within buildings as permanent wiring or bury them in ground or install them overhead. You need not always encompass them in a structure. You can run them exposed too. Flexible cables are great for mobile machinery, tools, and portable equipment.

Designed to suit purpose

Electric power cables are structured as per:

• Application purpose

• Voltage

• Current to be transferred

• Maximum temperature of operation

Examples:

• For wind power plants, cables need to be UV-protected and flexible with a sturdy sheath

• For mining purpose, cables need to have extra mechanical strength and double armoring

Advantages of underground cables

• They are less prone to damage through environmental factors and weather conditions like lightning, storms, rain, wind, and others

• They are low maintenance

• They show fewer incidents of faults

• They show smaller voltage drop

• They provide a better overall appearance

Power cable rating

1. Short circuit

Size of conductor required for installation depends on its ability to handle short-circuit instead of steady current. Short circuit is featured by a sudden flow of current for several cycles and then followed by a steady flow for a short period. This happens until the protection switchgear runs, usually between 0.1-0.3 seconds.

2. Voltage drop

Design of electric power cable depends on the maximum voltage drops from current source to load it allows.

In this case, Ohm’s Law comes into play: V=IR.

While determining voltage drop capacity, factors that operate include:

• Material used for wire manufacture: Copper is the first choice. Copper wire is a great conductor and features lesser voltage drop than a wire made of aluminum.

• Size of wire: Wires with greater diameters tend to show less voltage drop than those with smaller diameters of the same length.

3. Capacity to transfer current

Safe current transfer capacity of underground cables is known by the maximum permissible rise in temperature. Cause of rise in temperature indicates the losses that happen in an electric power cable and appear as heat.

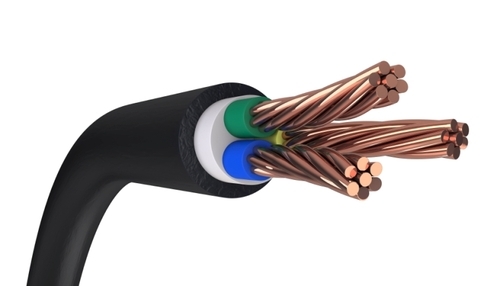

Power cable components

Conductor, insulation, inner sheath, armor, outer sheath – these are the “layers” of a power cable.

Facts:

• Conductor is the only component that carries electric current.

• Insulation of a cable is usually done through PVC (Poly Vinyl Chloride) or rubber or XLPE (Cross Linked Polyethylene).

• The inner sheath is generally present in multi core cables. It serves as binder for multiple conductors and as bedding for armoring material.

• Armoring is done for safety and to provide earthing shield to conductors. This is important in case of insulation failure. The fault current gets adequate paths to flow within the armor.

• Outer sheath gives protection from external damaging elements. It is made from PVC or rubber.

It is important to choose the right electric power cable as per your requirement and current suitability. Rajasthan Electric are experts in offering supreme quality cables and wires.