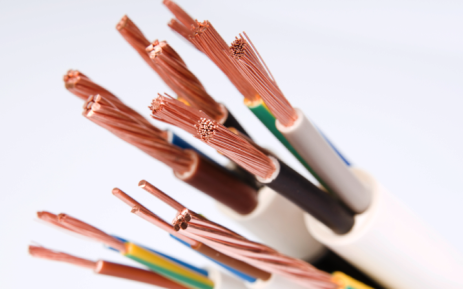

Control cables are electrical cables that are specifically designed for transmitting signals or data between different components in industrial automation systems. These cables are used to control and operate various machines and equipment, including sensors, actuators, motors, and other devices, that are integral parts of automated processes.

Control cables play a critical role in industrial automation systems, as they are responsible for transmitting signals and data between different components. Without control cables, it would be impossible to control and operate machines and equipment in an automated environment, leading to reduced efficiency, productivity, and increased downtime.

The purpose of this blog post is to provide an overview of control cables, their importance in industrial automation, and their different types, construction, and applications.

Types of control cables

Control cables are generally classified based on their construction, insulation material, and application. The basic principles of control cable include their ability to transmit signals or data reliably and efficiently, their resistance to mechanical and environmental stresses, and their ability to meet specific electrical requirements.

There are several types of control cables commonly used in industrial automation systems. PVC control cables are a popular option due to their flexibility, durability, and resistance to oil and chemicals. XLPE control cables, on the other hand, offer better resistance to heat and higher voltage capacities. Other types of control cables include LSZH cables, PUR cables, and rubber cables, each with their own unique properties and applications.

The properties of each type of control cable depend on factors such as the insulation material, conductor size, number of cores, and shielding. For example, PVC control cables typically have a temperature range of -15°C to +70°C and a voltage rating of up to 300V. XLPE control cables, on the other hand, have a temperature range of -40°C to +90°C and a voltage rating of up to 1000V. LSZH cables are known for their low smoke and zero halogen properties, making them suitable for use in areas where fire safety is a concern. PUR cables are highly resistant to oil and abrasion, while rubber cables are flexible and ideal for use in harsh environments.

Applications of control cables in industrial automation systems

Control cables play a crucial role in transmitting data and signals between different components in industrial automation systems. They are essential for controlling and operating machines, equipment, and devices in automated environments, enabling real-time communication and control.

Control cables are used in various types of automation systems, including factory automation, process automation, and building automation. In factory automation, control cables are used to control and operate machinery, assembly lines, and material handling systems. In process automation, they are used in chemical processing plants, refineries, and other industrial applications. In building automation, they are used to control lighting, HVAC systems, and security systems. Overall, control cables are essential components in industrial automation systems, providing reliable and efficient communication and control between different components.

Factors to consider when selecting control cables for industrial automation systems

Selecting the right control cable for an industrial automation system is crucial to ensure its reliable and efficient operation. There are several factors to consider when selecting control cables, including environmental factors, electrical characteristics, and mechanical properties.

Environmental factors to consider include temperature range, moisture exposure, and exposure to chemicals or other corrosive substances. Electrical characteristics such as voltage rating, current capacity, and impedance also play a significant role in selecting the appropriate control cable. The mechanical properties of the cable, such as flexibility and durability, also need to be considered, as they can affect the cable’s performance and longevity.

Importance of maintenance and troubleshooting of control cables

Maintaining and troubleshooting control cables is essential to ensure their reliable and efficient operation. Common issues that can affect the performance of control cables include damage to the insulation, corrosion, and mechanical stress. Over time, these issues can lead to signal degradation, intermittent faults, and system failures.

To maintain control cables, regular inspections, cleaning, and protection are necessary. Inspections can help identify any signs of wear, corrosion, or damage to the cable, while cleaning can help remove any contaminants that may affect the cable’s performance. Protecting the cables from harsh environments, such as exposure to chemicals or extreme temperatures, is also essential to prevent damage.

When problems arise with control cables, troubleshooting techniques can help identify and resolve them quickly. Techniques such as continuity testing, insulation resistance testing, and visual inspections can help locate faults and determine the extent of any damage. By addressing issues promptly, it is possible to avoid costly downtime and ensure that automation systems operate reliably and efficiently.

Conclusion

Selecting the right control cable for industrial automation systems is critical to ensure reliable and efficient operation. It is essential to consider factors such as environmental conditions, electrical characteristics, and mechanical properties when selecting control cables. Regular maintenance and troubleshooting are also crucial to identify and resolve issues promptly and prevent downtime.

By selecting the appropriate control cable and implementing proper maintenance procedures, industrial automation systems can operate efficiently and reliably, leading to increased productivity and reduced downtime. It is crucial to work with professionals who can provide guidance and support in selecting the right control cable and implementing proper maintenance and troubleshooting procedures to ensure the best results.