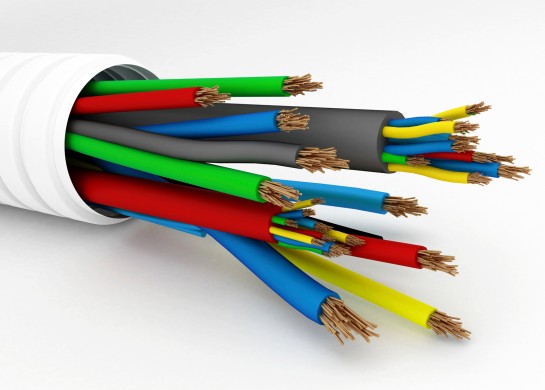

PVC insulated wires or the Polyvinyl chloride wires are extensively used for making cables. They are used for insulation purposes and for sheathing and bedding purposes. With the years, PVC insulated wires have started replacing the rubber insulated wires which were used for household wiring needs. These PVC wires are easier to process and they are very cost-effective. They last longer, more than 30 years.

Why are PVC insulated wires popular?

• Perhaps the main reason why PVC insulated wires have become so popular among electrical industries is because they are highly versatile. They can be conveniently modified with lubricants, stabilizers and plasticizers which help to enhance its properties. Processing and recycling these wires also becomes simple and hassle-free.

• PVC insulated wires are also found to be highly useful because they can be used for a variety of tasks in different industries. It can be easily softened by heating through a method which is called polymerization.

• Besides, PVC wires are also highly ductile, tough and resistant to abrasion. They are lightweight but very strong wires and highly resistant to rusting or abrasion or impact or weathering. This makes the PVC wires useful for outdoor products which are exposed to fluctuating temperatures and also for products which need to last long.

• PVC insulated wires are most useful for cable insulation. Because of its resistance to fire and ease of use these wires have been most widely used for cable production. Its durability also makes these wires ideally suited or construction of cables for modern buildings. Since they will never conduct electricity, they are best suited for electrical applications. So, you will find them used mostly for insulating cables and wires because they can last for more than four decades at a stretch.

• Another advantage of using PVC insulated wires is that they are absolutely safe for use. They are subjected to a lot of testing and research to ensure that they comply with all safety regulations. They are also non-toxic and found to be not as harmful for the environment as its rivals. Though the wires may burn when these are exposed to fire, they can cease to burn when the source of fire has been dealt with. It is interesting to note that instead of producing burning drops, they are likely to get charred only. So, the chances of the fire escalating or spreading fast are curtailed.

• Finally, PVC insulated wires are very easy to use and maneuver. They are therefore preferred for home goods, primarily because of their resistance to fire. They are cost-friendly because the costs of making them are quite low as materials for production are easily available than most other natural resources. Since they last long, they do not have to be replaced very often, thereby allowing buyers to enjoy cost-savings.

In this way, PVC insulated wires are preferred by buyers for making goods in a variety of industries. As they themselves do not conduct electrical current, they are perfect for use by electrical industries for making insulated wires and cables.