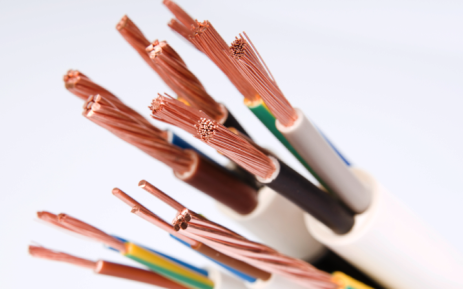

Copper wire cables have widespread use, especially in the electrical industry. Due to certain striking features, this metal is one of the favorites in the electrical world. In spite of the fact that copper has competition with fiber-optics, which is found to perform better than this metal, copper has a lot of takers.

Electrical conductivity

Copper shows super conductivity among all non-precious metals. Among precious metals, silver beats copper. Wires made of copper can handle a heavier electrical load with lesser armoring and insulation.

Due to the metal’s super conductivity, annealed copper has become the international standard. All other conductors of electricity are compared to it. The International Electrotechnical Commission, in 1913, defined conductivity of pure copper for commercial use as 100 per cent IACS (International Annealed Copper Standard) = 58.0 MS/m at 20 degree Celsius.

Annealed copper

Metallurgy defines annealing as a heat treatment that changes physical and sometimes chemical characteristics of a matter, consequently increasing its ductility and decreasing its hardness. This makes it more workable.

Metals like silver, copper, brass, and steel are heated for a while till they glow and are then allowed to cool at room temperature slowly in still air. Except steel, metals like silver, copper, and brass can also be cooled quickly by quenching them in water. As a result, the metals soften and can be then molded and shaped according to applications.

Other features of copper

- Copper shows high heat resistance. So, copper wire cables show fewer issues of overloading.

- Copper wires show high resistance to corrosion. However, they are prone to oxidation that creates a film of tarnish called patina over them; but this does not decrease their functionality.

- Due to high ductile nature of copper, it is possible to create wires thinner than a human hair out of it.

- The metal is also conducive for making thick cables for electrical posts.

- Copper shows high tensile strength, which is the measure of force needed to pull a wire till it breaks. Copper wires don’t break easily when stretched. This prevents electrical interruptions and failures.

- The metal shows a unique combination of high ductility and high strength. This is unlike other strong metals that show less pliability. This unique property of copper allows it to be twisted, bent, and pulled without breaking. It makes the metal ideal for wiring.

- Copper shows high creep resistance. Creep is the slow deformation of a metal due to constant contractions and expansions under conditions of “load” and “no-load.” This can lead to loose terminations, heated connections, and other dangerous electrical problems. Copper’s high creep resistance reduces such dangers. It poses fewer issues of loose connections. This, in turn, requires less maintenance for checking terminals for loose connections.

Manufacturers like Rajasthan Electric are experts in providing PVC wires & cables, copper wires, nickel copper wire, silver plated copper wire, enameled wires, stranded copper wire, bare copper strip, tinsel copper wire, tin coated copper wire, braided copper wire, and other products used for wiring, conductors, electrical boards and appliances, and more.