Copper flat wire is a specialized form of electrical conductor renowned for its efficient transmission of electricity. Copper, a highly conductive metal, is widely used in electrical applications due to its excellent conductivity and corrosion resistance. Its atomic structure allows for easy movement of electrons, making it ideal for conducting electricity with minimal resistance.

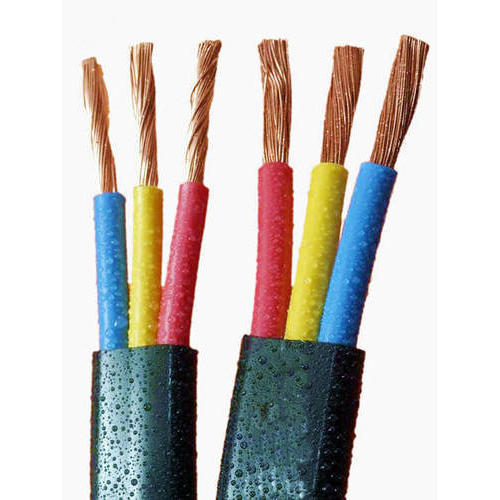

Flat wire, as the name suggests, is characterized by its flattened cross-sectional shape compared to traditional round wire. This structure offers several advantages, including enhanced surface area for heat dissipation, reduced skin effect, and improved efficiency in applications requiring high-frequency signals or power transmission.

The properties of copper flat wire make it suitable for a wide range of applications, including transformers, motors, generators, and electronic components. Its flexibility allows for easy bending and shaping, making it adaptable to various installation requirements. Additionally, copper’s high thermal conductivity ensures efficient heat dissipation, contributing to the overall reliability and longevity of electrical systems.

Thermal Conductivity of Copper Flat Wire

Copper is renowned for its exceptional thermal conductivity, making copper flat wire an excellent choice for heat management applications.

The exceptional thermal conductivity of copper stems from its atomic structure and metallic bonding. Copper atoms are closely packed in a crystalline lattice, allowing heat to travel quickly through the material via the movement of free electrons. This efficient transmission of heat is why copper is widely used in heat sinks, radiators, and other cooling systems.

Compared to other materials, copper’s thermal conductivity stands out. It surpasses materials like aluminium, steel, and most alloys, making it one of the most effective conductors of heat available. This property makes copper wire particularly advantageous in applications where rapid heat dissipation is crucial, such as in high-power electronic devices and industrial machinery.

The use of copper flat wire enhances heat management in various ways. Its flat structure provides a larger surface area compared to round wire, improving contact with heat sinks or cooling elements. This increased surface area allows for more efficient heat transfer, reducing the risk of overheating and improving the overall performance and reliability of electrical systems.

Benefits of Using Copper Flat Wire for Heat Transfer

Copper flat wire offers numerous benefits for heat transfer applications, particularly in electronic devices and heating systems. In electronic devices, efficient heat dissipation is crucial for maintaining optimal performance and preventing overheating-related failures. Copper flat wire’s high thermal conductivity allows heat to dissipate quickly, reducing the risk of components reaching critical temperatures. This is especially important in devices like computer processors, power converters, and LED lighting systems, where excess heat can degrade performance and shorten lifespan. The flat wire structure further enhances heat dissipation by providing a larger surface area for contact with heat sinks or cooling solutions, ensuring effective thermal management. Additionally, copper flat wire finds extensive use in heating elements and systems due to its ability to conduct heat rapidly and evenly. This makes it ideal for applications such as industrial furnaces, electric stoves, and radiant heating systems. The flat wire design allows for precise temperature control and uniform heating, enhancing energy efficiency and overall performance in heating applications.

Factors Influencing the Thermal Performance

The thermal performance of copper flat wire is influenced by several key factors that impact its ability to conduct and dissipate heat effectively.

Wire thickness and surface area play a significant role in thermal performance. Thicker wires generally have lower electrical resistance and can carry more current without overheating. However, thinner flat wires may offer increased flexibility and easier installation in compact spaces. The surface area of the flat wire also affects heat dissipation; larger surface areas allow for better contact with cooling elements, enhancing thermal conductivity and improving overall performance.

Environmental factors and operating conditions also influence thermal performance. Ambient temperature, humidity levels, and airflow around the flat wire can impact its ability to dissipate heat. High ambient temperatures or poor airflow can reduce the effectiveness of heat transfer, leading to increased operating temperatures and potential performance issues. Additionally, operating the flat wire near its maximum current-carrying capacity for extended periods can result in elevated temperatures and reduced thermal efficiency.

Considering these factors is essential when designing and utilizing copper flat wire for thermal management applications. Optimizing wire thickness, surface area, and operating conditions can maximize its thermal performance and ensure reliable heat dissipation in various environments.

Summing Up!

Copper flat wire stands out as a versatile and efficient solution for heat transfer and thermal management applications. Its exceptional thermal conductivity, derived from the atomic structure of copper and enhanced by the flat wire design, enables rapid and efficient heat dissipation. This makes copper flat wire an ideal choice for various industries, including electronics, heating systems, and industrial equipment.

The benefits of using copper flat wire for heat transfer are evident in its ability to maintain optimal operating temperatures in electronic devices, preventing overheating and ensuring long-term reliability. Additionally, its precise temperature control and uniform heating make it invaluable in heating elements and systems, contributing to energy efficiency and performance.

Factors such as wire thickness, surface area, environmental conditions, and operating parameters significantly influence the thermal performance of copper flat wire. By carefully considering these factors and optimizing the design and installation of flat wire solutions, manufacturers and engineers can harness the full potential of copper flat wire for effective heat management.

Thus, copper flat wire represents a technologically advanced and reliable option for addressing thermal challenges, making it a preferred choice across diverse industries where efficient heat transfer and thermal stability are paramount.